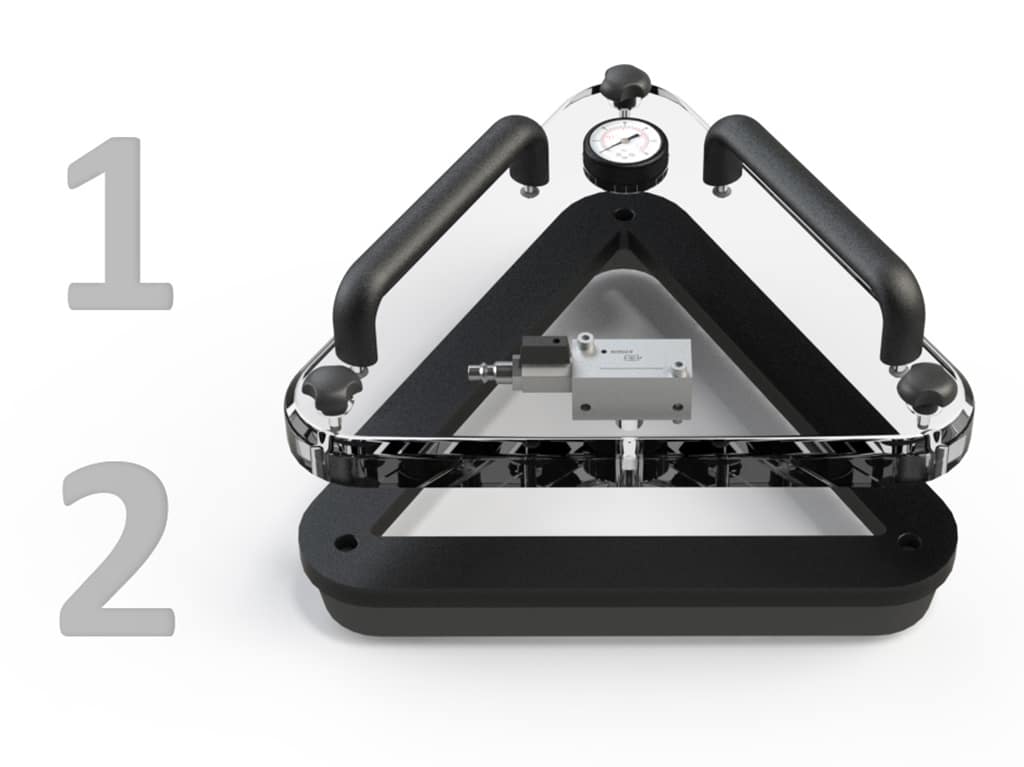

Corner Vacuum Box for Leak Testing with Interchangeable Base (BAV-40IC)

Non-contractual photo

Easily control the tightness, waterproofing of your welds and sheets with the new generation BAV40IC vacuum box with interchangeable base.

The BAV40IC is an NDT vacuum box designed for internal right-angle corners, tailored for leak testing 90° internal corner welds, such as inside mechanically welded assemblies, tanks, containers, on the corners of flat roofs, terrace roofs with waterproofing membranes, and more. Its interchangeable base offers great flexibility for inspecting different surfaces and weld configurations, enabling rapid leak detection.

PRESENTATION ET APPLICATIONS

he BAV40IC is a vacuum box, also known as a bubble box, specially designed for checking the tightness of internal right-angle corners (configuration 3), for example:

- Mechanically welded assemblies

- Ship tanks

- Waterproofing membranes for roofs, flat roofs, or terrace roofs

- Any other right-angle surfaces (metallic or non-metallic) where a pressure gradient can be applied

Its two-part design consisting of the main body and an interchangeable base addresses the challenges of equipment maintainability (maintenance), versatility, and ensures good readability of indications (height of the viewing window).

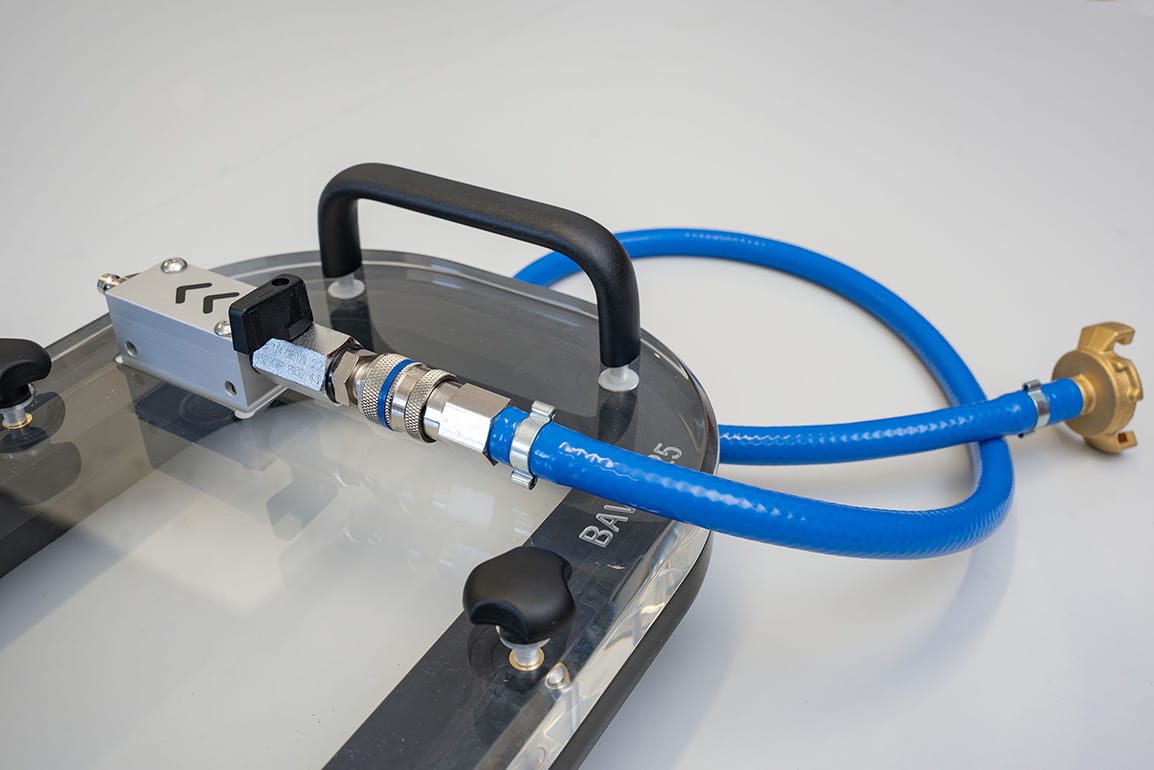

Our vacuum box can operate either by compression using the venturi system or by suction using our specially adapted optional vacuum pump.

KIT COMPOSITION (excluding options):

- Main body/reading chamber comprising:

- Handling grips

- Vacuum gauge

- Hybrid vacuum system:

- By venturi effect / using a compressor

- By suction / using a vacuum pump

- Vacuum adjustment valve for:

- Flow limitation when using a compressor

- Leakage flow when using a vacuum pump

- Quick base attachment system

- 50 cm extension with a quick female connector to cat’s head (Vacuum by venturi effect / compressor)

- Interchangeable internal corner right angle base comprising:

- Seal between the reading chamber and the base

- Interface foam with the surface under inspection

AVANTAGES

Performance

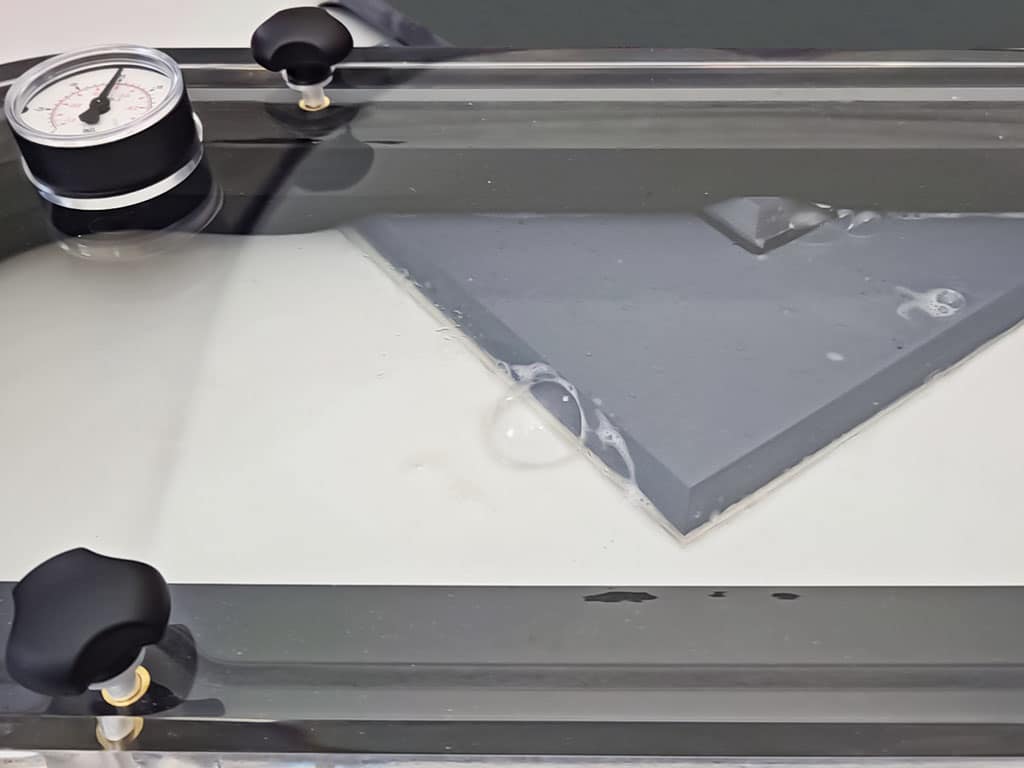

2cm viewing window to ensure clear and reliable reading of indications

Durable and resistant foam

Triangular geometry to increase relative pressure on the foam and allow maximum deformation on the surface of the inspection area.

FEATURES

Two-Part Modular Design

Two-Part Modular Design

Easy Reading of Indications

Vacuum by Venturi Effect

Vacuum by Vacuum Pump

Options

Hardened transport case

To safely transport your vacuum box, we offer a hardened transport case with a machined imprint in the shape of the vacuum box to prevent any movement.

Gauge with calibration certificate

We standardly provide a CE-certified but uncalibrated gauge. Therefore, we offer an option of a calibrated gauge with a verification certificate for your standardized inspections.

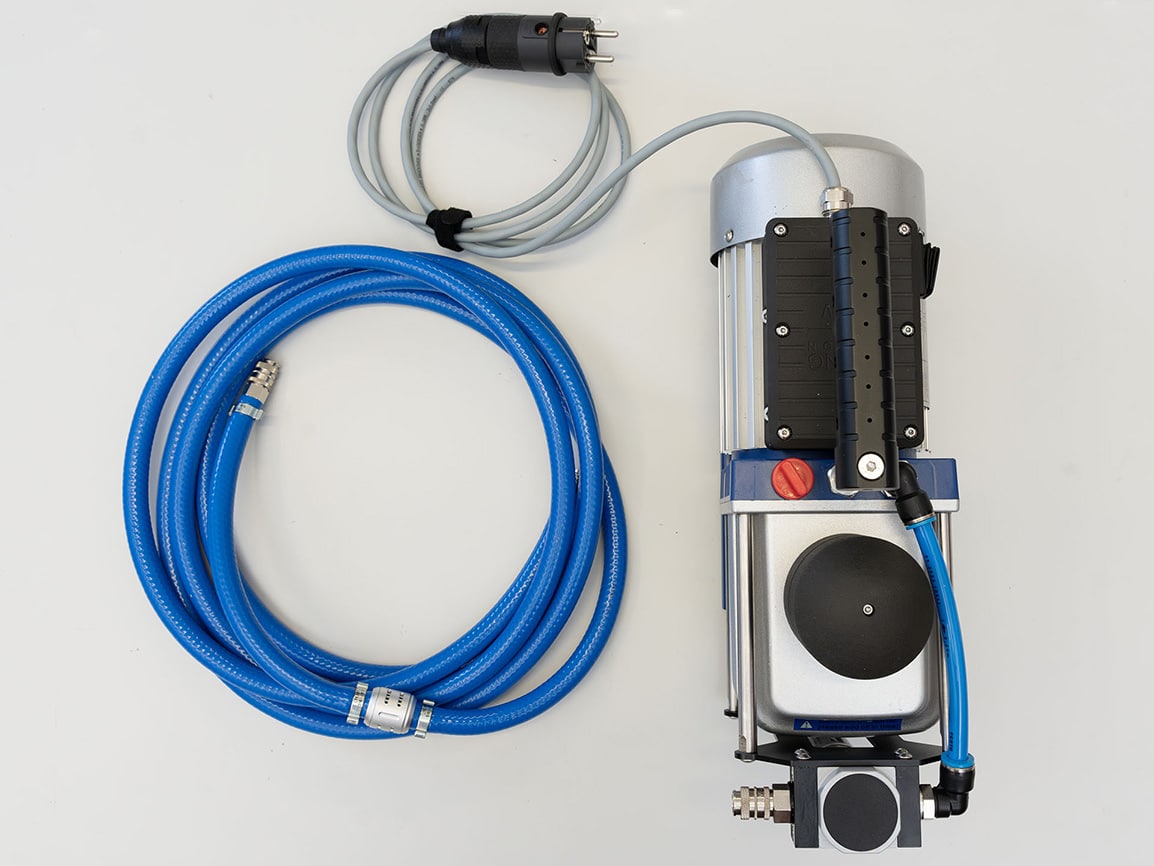

Vacuum pump PAV-2209

To use the vacuum box in suction mode with a vacuum pump. We offer a customized 220V 9CFM vacuum pump adapted for field conditions. The optional “vacuum pump” pack includes a 2-meter pneumatic hose with our innovative flow regulation and rapid depressurization

Features

| TECHNICAL SPECIFICATIONS | Details |

|---|---|

| Dimensions | 490 mm x 270 mm x 130 mm |

| Weight | 4200 g |

| Materials | Main body: Aluminium alloy, Plexiglas Base: Plexiglas, closed-cell foam |

| Gauge | -1 Bar |

| Vacuum Generator Type | Hybrid system: - Venturi Effect: Requires a compressor of 10m3/hour at 8 bar - Vacuum pump (optional) |

| Foam Type | Closed cell foam |

| Foam Height | 35 mm |

| Foam Hardness | 40/50 Shore 00 |

-

Product brochureProduct brochure