MAGNETIX 2.0 (mgn2)

Non-contractual photo

Reinvent your magnetic particle inspections with MAGNETIX Power pack 2.0, the ultimate portable MPI solution for your field inspections.

The MAGNETIX Power pack 2.0 Portable Magnetic Particle Inspection (MPI) Kit offers a complete mpi yoke battery solution for MT Non-Destructive Testing (NDT MT) for metallic inspections. Engineered for optimal field use, this battery powered electromagnetic yoke package combines compactness, lightweight features, and ultra-ergonomic design. Its power management system, controlled by a microcontroller, offers unparalleled reliability and performance in the industry.

This product is obsolete

Context and Scope of Application:

The MAGNETIX Power pack 2.0 Portable Magnetic Particle Inspection (MPI) Kit is designed for Non-Destructive Testing (NDT) professionals who need a portable battery powered MPI yoke for field-based MPI (NDT MT). Its rugged and compact design makes it ideal for use in challenging and varied environments. Our inverter, managed by a microcontroller and specially developed for powering MPI yokes, provides unparalleled reliability and robustness in the field of portable magnetic particule inspection.

Complete Guide to Magnetic Particle Inspection for Non-Destructive Testing (NDT MT)

Introduction

Magnetic Particle Inspection is a Non-Destructive Testing (NDT MT) technique that allows for the detection of surface and sub-surface imperfections in ferromagnetic materials. This method is fast, efficient, and can be implemented using various types of equipment, including portable and mobile MPI systems.

Operating Principle

The core of the MT inspection method involves inducing a magnetic field into the test piece. The field can be created by different means, such as a battery-powered electromagnet or a magnetic particle inspection clamp. Material discontinuities disrupt this field, attracting magnetic particles from a colored or fluorescent indicator product to form visual indications.

Magnetization

The test piece can be magnetized by several methods, including:

- Direct contact magnetization with electrodes

- Coil wrapping around the piece

- Bench magnetization

- …

Indications

Indications are generally made visible using liquids containing magnetic particles, which may be colored or fluorescent.

Applications

MPI is regularly used for NDT MT inspections across several industries, including:

- Aerospace

- Shipbuilding

- Automotive

- Petrochemical Industry

- Civil Engineering

Advantages

- Rapid and efficient detection of surface and sub-surface defects

- Applicability to complex geometric shapes

- Easy implementation of inspections

- Comprehensive method

Limitations

- Applicable only to ferromagnetic materials

- Difficulty in detecting underlying discontinuities

- Sensitivity to surface conditions, such as cleanliness and roughness

- Use of chemical products

Standards and Specifications

Magnetic Particle Inspection is regulated by a series of standards that provide detailed guidelines on how tests should be performed to ensure performance. Current standards include, among others:

- NF EN ISO 9934-1: Non-destructive testing – Magnetic particle testing – Part 1: General principles

- NF EN ISO 9934-2: Non-destructive testing – Magnetic particle testing – Part 2: Detection media

- NF EN ISO 9934-3: Non-destructive testing – Magnetic particle testing – Part 3: Equipment

ASTM E709: Guide for Magnetic Particle Testing

Conclusion

The NDT MT method of Magnetic Particle Inspection is a comprehensive, fast, and easy-to-implement inspection technique. It is widely applied across various industrial sectors to ensure the quality and safety of metallic structures. Magnetic Particle Inspection Kits are often available to facilitate the application of this essential technique.

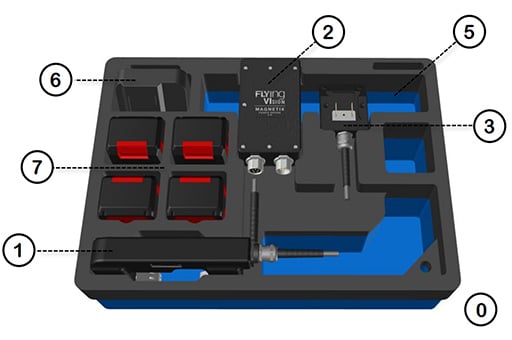

Nomenclature

- MGN2 (Complete MPI battery pack)

- MGN2-A400 (MPI battery powered yoke)

- MGN2-A100 (AC / DC MPI Power driver)

- MGN2-A200 (MPI Battery rack)

- MGN2-A500 (MPI yoke holder)

- Charger

- Battery (18V 4.0Ah)

Benefits

Performance

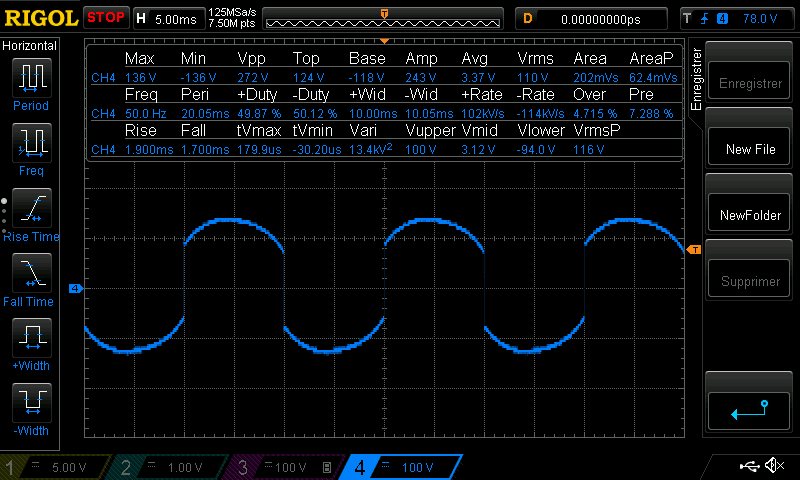

With a magnetic excitation of 3000A/m, our system ensures precise detection of defects. The use of a near-perfect sine wave alternating current from the inverter guarantees flawless detectability of indications.

Quality

Our system is manufactured with high-quality materials such as aluminum alloy, stainless steel, and polyurethane, ensuring enhanced durability and resistance.

Security

The system features protection against short circuits and an LED user interface for safe and user-friendly operation.

Ergonomics

The rugged ultra-portable system is designed to be compact, lightweight, and ergonomic, making it ideal for use in challenging field inspections conditions.

Reliability

Designed in our Engineering Department using high-quality materials and innovative techniques, the MAGNETIX MPI Power pack 2.0 has undergone rigorous testing in challenging conditions. Its reliability is ensured by an intelligent microcontroller that manages the inverter, ensuring optimal performance even in the most demanding testing environments.

FEATURES

User interface

The LED user interface provides real-time status updates and allows for seamless communication with the MPI inspection system.

Duty cycle

The microcontroller manages the usage time to ensure the reliability and safety of the MPI system, with a duty cycle of 25%.

Battery management

Intelligent, safe energy management via microcontroller

User interface

The LED user interface provides real-time status updates and allows for seamless communication with the magnetoscope system.

Duty cycle

The microcontroller manages the usage time to ensure the reliability and safety of the MPI system, with a duty cycle of 25%.

Gestion des batteries

Intelligent and secure energy management is ensured through the use of a microcontroller.

Quick connection of peripherals

Reinforced quick connectors and hydrocarbon-resistant, tear-resistant PU cables are used. The cables are protected at the cable gland level by injection-molded polyurethane strain relief.

Ultra portability

A compact and ergonomic complete system is provided to perform inspections in the most hard-to-reach areas.

Excitation of the electro magnetic yoke

High-quality activation switch for the MPI yoke.

Quick connection of peripherals

Reinforced quick connectors and hydrocarbon-resistant, tear-resistant PU cables are used. The cables are protected at the cable gland level by injection-molded polyurethane strain relief.

Ultra portability

The LED user interface provides real-time status updates and allows for seamless communication with the MPI inspection system.

Excitation of the electro magnetic yoke

High-quality activation switch for the MPI yoke.

Composition of the kit

- 1 x DC MPI electromagnetic testing yoke

- 1 x MPI DC / AC Power driver (inverter 18V / 220V)

- 1 x Belt with fastening systems

- 1 x MPI Battery Charger

- 1 x DC Battery 18V 4,0 Ah

- 1 x Rugged MPI carrying case

Characteristics

| Technical characteristics | Details |

|---|---|

| Package mass | 5kg (with battery) |

| Autonomy | 1h at 100% use, 4h at 25% use (for a 4Ah battery) |

| Magnetic excitation | 3000 A/m |

| Lifting force | 5,5kg |

| Protection | IP54 |

| Voltage IN (Battery) | 16,8V - 21,0V |

| Voltage OUT (Clamp) | 205V - 230V |

| Current IN | 0,1A - 12,0A |

| Current OUT | 0,0A - 10,0A |

Downloadable files:

-

PresentationPresentation