Magnetix MGN3: Battery-Powered AC Magnetic Yoke for Magnetic Particle Inspection

Non-contractual photos

Looking for the ultimate solution for your field magnetic particle inspections ? The MAGNETIX MGN3 is the perfect magnetic yoke, designed to enhance your MT inspections in the toughest environments, delivering unmatched efficiency and performance thanks to its state-of-the-art design and advanced capabilities.

More than just an evolution of our magnetic particle inspection battery-powered yoke, the Magnetix MGN3 is a true revolution in the market of magnetic particle inspection equipment.

Our brand-new version of the now well-known Magnetix battery powered AC mag yokes sets new standards for safety, performance, reliability, and ergonomics in the field of magnetic particle testing.

The ultra-ergonomic design of our magnetic yoke enables inspections in the most hard-to-reach places, while its 42V AC 50/60 Hz operation allows for safe NDT MT inspections in metallic environments, eliminating the risk of electrical shock.

This cutting-edge device offers reliability and performance levels that meet all magnetic particle testing requirements and will undoubtedly make it the market reference for portable MPI battery yokes.

PRESENTATION ET APPLICATIONS

Our MAGNETIX series of battery-powered magnetic particle inspection yokes was specifically developed to meet the demanding requirements of field-based magnetic particle testing.

This type of inspection presents several challenges, including the need for autonomy, system safety, performance, reliability, and ergonomics. Compactness is also essential for freedom of movement, and the magnetic yoke system must be lightweight enough for prolonged, comfortable use.

With a new form factor and advanced technologies, this latest version of our magnetic particle equipment addresses all these needs. Additionally, the choice to use a 42V operating voltage significantly enhances electrical safety for the user.

Many clients prohibit the use of equipment exceeding 48V in metal enclosures, so this new battery-powered MPI mag yoke version is the ideal solution for this safety concern.

The ultra-innovative design of our new MAGNETIX version significantly enhances work comfort in field environments where space constraints and mobility are critical factors, such as rope-access magnetic particle inspections, confined space work, MT inspections on piping racks, scaffolding, and general on-site MPI inspections.

As with any portable power tool, the key advantage of no longer needing a power outlet is the freedom to move around without the risk of getting tangled on obstacles. This flexibility improves both ease of use and efficiency for your magnetic particle inspections.

Recognizing the recurring reliability issues with magnetic inspection equipment, particularly regarding yoke connectors, we have placed special emphasis on this aspect. Our solution provides a durable and robust mechanical design to maximize the strength and longevity of the system.

The MGN3 magnetic particle yoke kit represents the ultimate evolution of our battery-powered yokes, setting new standards in the industry.

KIT COMPOSITION (excluding options):

- One Fast single charger with one set of Li-ion batteries (Li-ion 2 x 3Ah for EU – 2 x 2.5Ah for FCC)

- MAGNETIX 42VAC Power driver with his belt and yoke support

- MAGNETIX 42VAC Heavy Duty Yoke

- Rugged transport case

Kits with CE certificate

- Ref : MGN3-1 – MAGNETIX 42VAC Standard Kit

- Ref : MGN3-2 – MAGNETIX 42VAC w/o batteru charger Kit

Kits with FCC certificate (avaibility End of 2024)

- Ref : MGN3-3 – MAGNETIX 42VAC Standard Kit

- Ref : MGN3-4 – MAGNETIX 42VAC w/o batteru charger Kit

Uncompromising reliability, safety and durability

1. Dual Battery

1 or 2 batteries

2. Monobloc Housing

6061 aero-grade alu

3. Backlighting

RGB LED

4. Core System

EMC filtering

5. Core System

EMC filtering

6. Compact Design

Optimized placement

7. Field Connector

IP68/metal

8. Boost Architecture

18 VDC/VAC

9. Microcontroller

10,000/s analysis

10. Protection

IP54, reinforced design

1. Dual Battery

1 or 2 batteries

2. Monobloc Housing

6061 aero-grade alu

3. Backlighting

RGB LED

4. Core System

EMC filtering

5. Core System

EMC filtering

6. Compact Design

Optimized placement

7. Field Connector

IP68/metal

8. Boost Architecture

18 VDC/VAC

9. Microcontroller

10,000/s analysis

10. Protection

IP54, reinforced design

ADVANTAGES

Performance

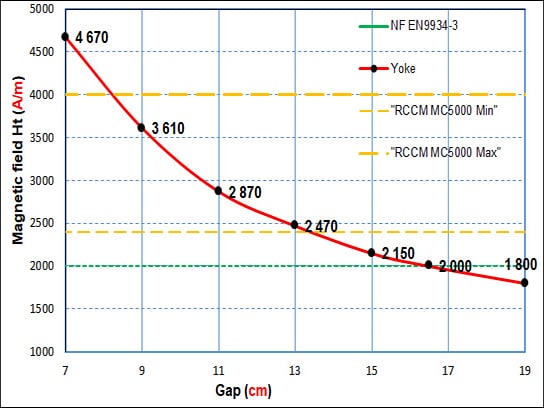

- Magnetic Field : Our advanced electronics combined with our high-performance magnetic yoke achieve tangential magnetic field levels that meet all market standards.

- Lifting capacity : The lifting capacities of our system easily exceed the minimum required 4.5 kg and are around 6 kg.

- Autonomy : The autonomy of our battery-powered magnetic particle yoke kit, when used at 25% of the 50% duty cycle (meaning the device operates for 25% of the total duty cycle), is up to 8 hours per battery set. For intensive use, where the MT yoke kit is used at 50% of the duty cycle (such as in workshop environments with continuous inspections), autonomy is reduced to up to 4 hours per battery set.

Availability of use

The MAGNETIX 42V AC combines a heavy-duty mag yoke with one of the highest real usage rates / duty cycle in the market and high-level power electronics to work under the most extreme conditions while maintaining top performance.

The duty cycle is set and managed by the microcontroller and is configured to 50%.

Ergonomics and Lightness

The ergonomics of our MPI battery yoke kit, the MGN3, have been extensively reworked based on customer feedback from previous versions. We’ve created a fully ergonomic system that sits as a belt around the inspector’s lower waist, complete with a support system to reduce lower back strain. The power driver is designed to be extremely slim, allowing it to navigate into tight spaces without concern about getting snagged. Its weight, design, and compact size makes our magnetic yoke an ideal tool for work in hard-to-reach areas.

Safety

We selected a 42V operating voltage to completely eliminate the risk of electric shock for operators, especially in degraded conditions where devices using voltages above 48V can pose a danger.

For example, a severed mag yoke cable during an inspection inside a metal enclosure.

Many clients prohibit the use of devices with voltages exceeding 48V in metal enclosures (storage tanks, vats, etc.).

The MAGNETIX 42VAC allows you to operate safely in all types of environments while delivering the best performance in the market of portable MPI kits.

Quality and Reliability:

Our mechanical and electronic design choices are focused entirely on maximizing performance and reliability.

The polyurethane cables (resistant to tearing and most chemicals) are reinforced at all connections with strain reliefs and metal cable glands.

Our extensive experience and feedback have allowed us to develop a product perfectly suited for the most demanding field conditions.

FUNCTIONALITIES

User interface

The power driver of our magnetic particle inspection battery kit, Magnetix, incorporates a microcontroller connected to a LED system. This feature communicates the system’s status and alerts the user to any potential problems.

There are two types of signals on our Magnetix power driver:

- A modulation of light, which conveys information about the system’s status, such as initialization, ignition, pre-standby, or duty cycle.

- Light flashing, indicating error messages, such as low battery, too high temperature, or abnormal current, etc.

Duty cycle management

To enable continuous magnetic particle inspections and maximize the usage time of your system, we have designed our AC electromagnetic yoke to ensure a usage factor, or duty cycle, of 50%.

The duty cycle defines the maximum recommended usage time before the electromagnet yoke can no longer effectively dissipate the heat it generates, and consequently, starts to overheat.

This factor is directly related to the dimensions of the metal legs / poles and therefore its ability to dissipate heat. The pole section of our mag yoke is 25 x 25 mm, or 6.25 cm².

Belt

The magnetic yoke is secured to the belt with an aluminium support featuring a smart magnetic self-locking system, which eliminates the need for complex handling to lock or unlock the yoke from the belt.

The 50mm belt height provides stable positioning for various components, reducing twists and significantly minimizing tension for the operator.

The belt is also equipped with a reinforced quick-release closure system and is adjustable on both sides of the buckles to fit waist sizes ranging from X to XX cm.

Cables and connectors

Cables and electrical connectors face significant wear during magnetic particle inspections, so we designed the power driver to include only the magnetic yoke’s power cable. This coiled cable is made of polyurethane, providing excellent resistance to hydrocarbons and high durability against cuts. To prevent pinching from excessive bending, the cable exits are reinforced with molded PU strain reliefs. Additionally, the connection to the power driver uses a metal-core connector to maximize longevity.

TECHNICAL CHARACTERISTICS

| Technical characteristics | Details |

|---|---|

| Working Voltage | 42V AC 50/60HZ |

| Pull Force / Lifting Capacity | About 6Kg with pole gap of 11cm |

| Input Voltage | 18V DC |

| Pole Section | 25 x 25 mm (6,25 cm²) |

| Duty Cycle | 50% |

| Protection Rating IP | IP 54 |

| Tangential magnetic field | >2000 A/m at 16,5cm* |

| Protection Rating IP | IP54 |

| Battery Capacity | 2 x 3Ah |

| Charging time for battery pack (2 batteries) | Dual charger: 1 h - Single charger: 2 h |

| Autonomy for standard field use ( 25% of Duty Cycle ) | Up to 8 hours |

| Autonomy for intensive field use ( 50% of Duty Cycle ) | Up to 4 hours |

| Total weight (excluding case) | 5Kg |

| Certifications | CE, UKCA, FCC pending |

* The general performances are indicative as they are specific to each system and may therefore vary slightly.

Fichiers téléchargeables :

-

PrésentationPrésentation

MAGNETIC YOKE MGN3 OPTIONS

UVW dual spektrum Yoke light - Ref : MGN3-A010

Removable dual-spectrum induction lamp (visible or UV-A) allows you to perform inspections in both visible and UV spectrums for fluorescent testing.

The lamp attaches to one of the poles of the MPI yoke in just seconds, with the magnetic field of the mag yoke powering the different light sources

TECHNICAL CHARACTERISTICS

| White light | UV-A light | ||

|---|---|---|---|

| Light intensity | 4500 Lux | UV Light intensity | 2500 μW/cm² : |

| Color temperature | 4000°K | Stray white light | < 20 Lux |