OUR SOLUTIONS FOR YOUR MAGNETIC PARTICLE TESTING (NDT MT)

Are you looking for a high-performance battery operated magnetic yoke system for conducting magnetic particle testing in the field? Flying Vision has developed a range of battery operated magnetic yokes with a level of performance, reliability, and ergonomics that make them a benchmark in the market for portable magnetic particle inspection equipment.

Discover our “Magnetix” range of battery ndt mpi yoke, as well as the essential accessories for conducting your magnetic particle inspections using an electromagnetic yoke.

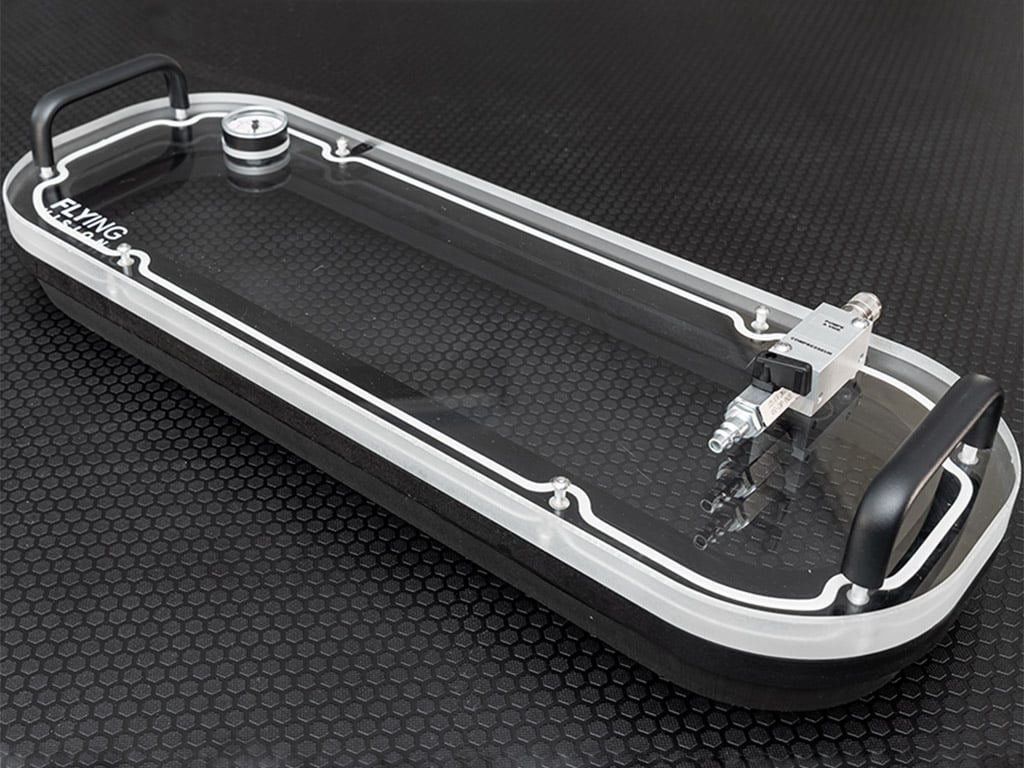

Our portable MPI yoke complete solutions « Magnétix »

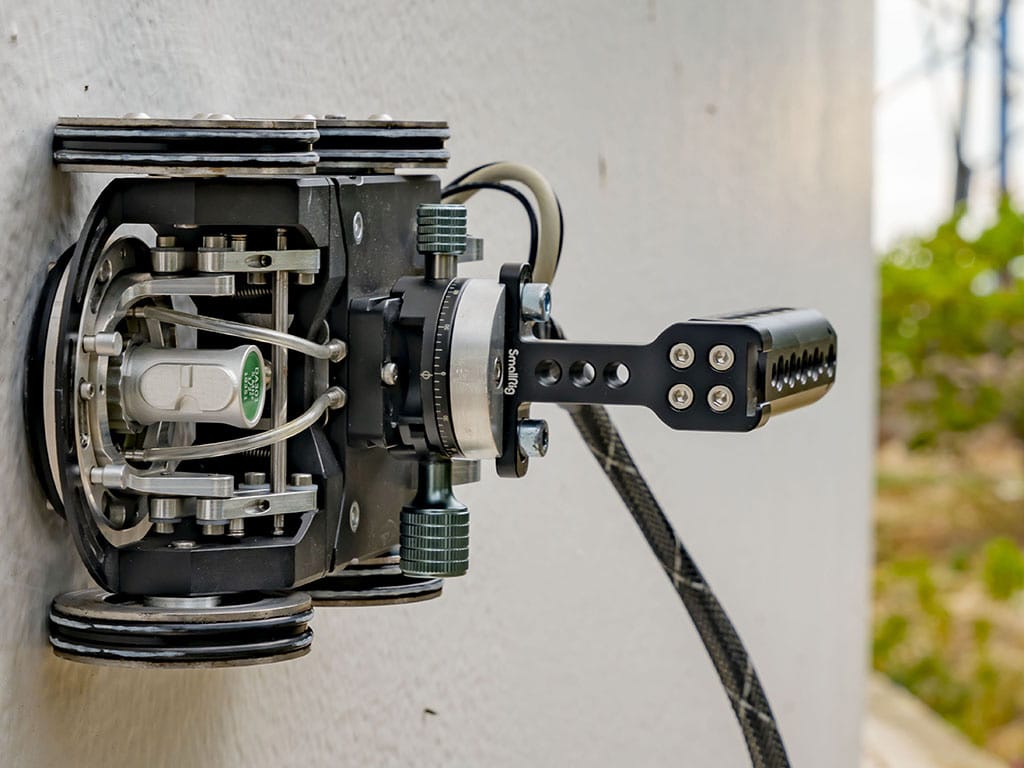

Magnetix MGN 3.0

Portable 42V AC Magnetic Particle Inspection Kit

More than just an evolution of our magnetic particle inspection battery-powered yoke, the Magnetix MGN3 is a true revolution in the market of magnetic particle inspection equipment.

Our brand-new version of the now well-known Magnetix battery powered AC mag yokes sets new standards for safety, performance, reliability, and ergonomics in the field of magnetic particle testing.

Magnetix MGN 2.5

Portable 220V AC Magnetic Particle Inspection Kit

An evolution of our portable magnetic particle inspection kit Magnetix 2.0, the 2.5 version features a mag yoke with an increased duty cycle, magnetic field, and robustness to meet the most demanding magnetic particle inspection needs. The output voltage of our mpi inspection kit MGN2.5 remains at 220V AC 50Hz.

Magnetix MGN 2.0

Portable 220V AC Magnetic Particle Inspection Kit

This product is obsolete

Our Magnetix 2.0 portable magnetic particle inspection kit revolutionizes your field magnetic particle testing with its ergonomic design, lightweight nature, and high performance. This portable magnetic particle testing equipment is equipped with an AC yoke operating at 220V 50Hz.

Our MPI welding test accessories

Battery-Powered AC Yoke for MPI inspection

Principles of Magnetic Particle Inspection

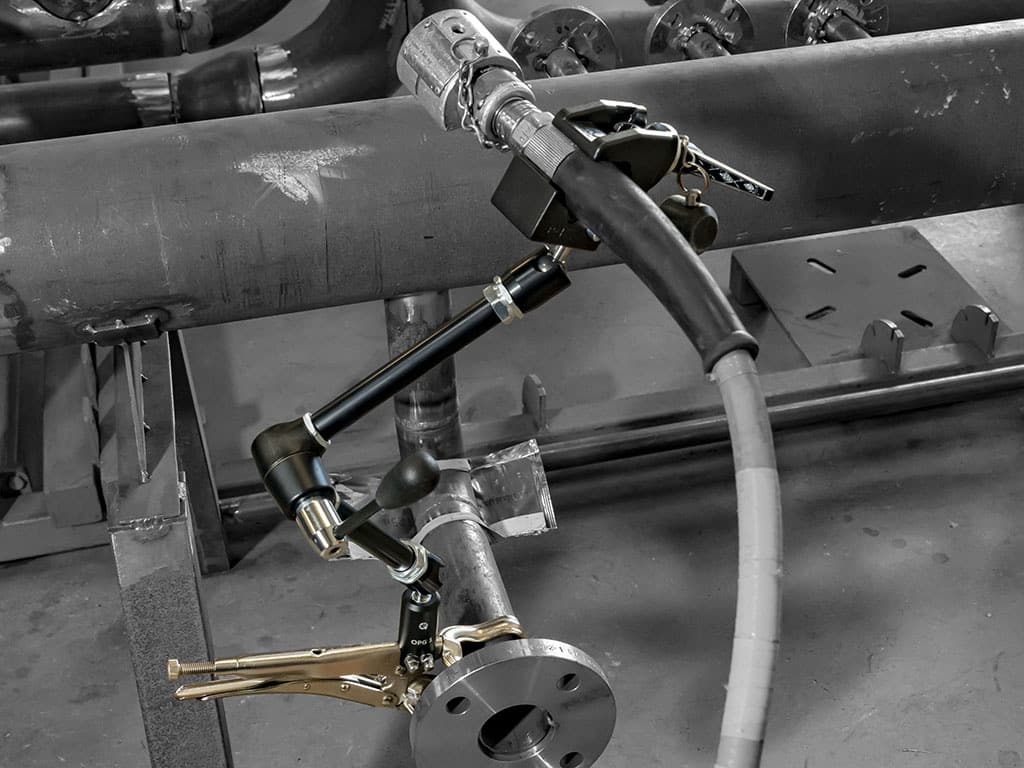

Magnetic particle testing is a non-destructive testing (NDT MT) technique used to detect surface or subsurface imperfections in ferromagnetic materials, such as iron or cast iron. This method is fast, efficient, and can be performed using various equipment, including portable and mobile magnetic particle testing systems.

The core of the magnetic particle inspection method involves inducing a magnetic field in the item being inspected. This field can be created using different means, such as a battery-powered electromagnetic yoke or a portable magnetic yoke. Discontinuities in the material disrupt this field and attract the magnetic particles of a colored or fluorescent indicator product to form visual indications.

Advantages of Battery-Powered NDT MPI Yokes

The primary purpose of portable magnetic particle testing kits is to enable autonomous inspections in areas lacking an electrical power source and to enhance mobility by eliminating the need for a long power cable that could hinder the inspector’s movement.

The applications and fields where this portable mpi magnetic particle inspection technology is used are numerous.

Functioning of mag particle weld testing:

Depending on the depth and type of defect sought, the magnetization of your magnetic particle inspection system must be performed using either a direct current (DC) or alternating current (AC) source. Generally, the detectable defects using different power sources for the electromagnetic ndt mpi yoke are as follows:

- Alternating Current (AC):

Detection of surface-breaking discontinuities / certain identification of very fine discontinuities

- Direct Current (DC):

Detection of subsurface discontinuities, noting that the detectability of subsurface defects greatly depends on the defect’s geometry and cannot be guaranteed to a certain depth

Given that most field inspections, conducted using magnetic yokes, require alternating current, we have developed a portable mag yoke kit range powered by this type of current named “MAGNETIX.”

During the development of this product, our specifications focused on resolving specific issues related to autonomous portable magnetic particle inspection.

Challenges in field mpi inspection :

Portability

Field magnetic particle inspections, including magnetic particle testing of welds, and general magnetic particle inspection NDT, are often carried out in confined and hard-to-reach areas. Therefore, it is imperative that the portable magnetic particle inspection kit be as compact and unobtrusive as possible. NDTMPI controllers also spend long hours conducting their inspections, so it is necessary for the magnetic yoke and the complete kit to be as lightweight as possible. To meet these requirements, we have developed the most compact possible power electronics and optimally sized the battery system to achieve the best possible weight-to-autonomy ratio.

Ergonomics

To enable the use of your Magnetix portable ac yoke in any position, the various components are arranged on a firefighter-type belt with a quick-release fastening. The length of the belt, the position of the mag yoke, the inverter, and the battery are adjustable. The ideal placement for these components is laterally at the hip level to allow bending without any discomfort. On one side, you have quick and easy access to the magnetic yoke with an automatic magnetic lock, and on the other, access to the inverter’s power switch and battery replacement.

Battery Life

The battery life of your portable mpi yoke system during your mpi magnetic particle inspection campaigns is a critical factor. Our Li-ion cordless batteries provide a runtime of 2 to 3 hours, depending on usage. This battery sizing allows for a total weight of the portable magnetic particle inspection system that is comfortably manageable for a full day of inspections. Compartments for spare batteries are included in the hardened transport case of the MAGNETIX.

Duty Cycle

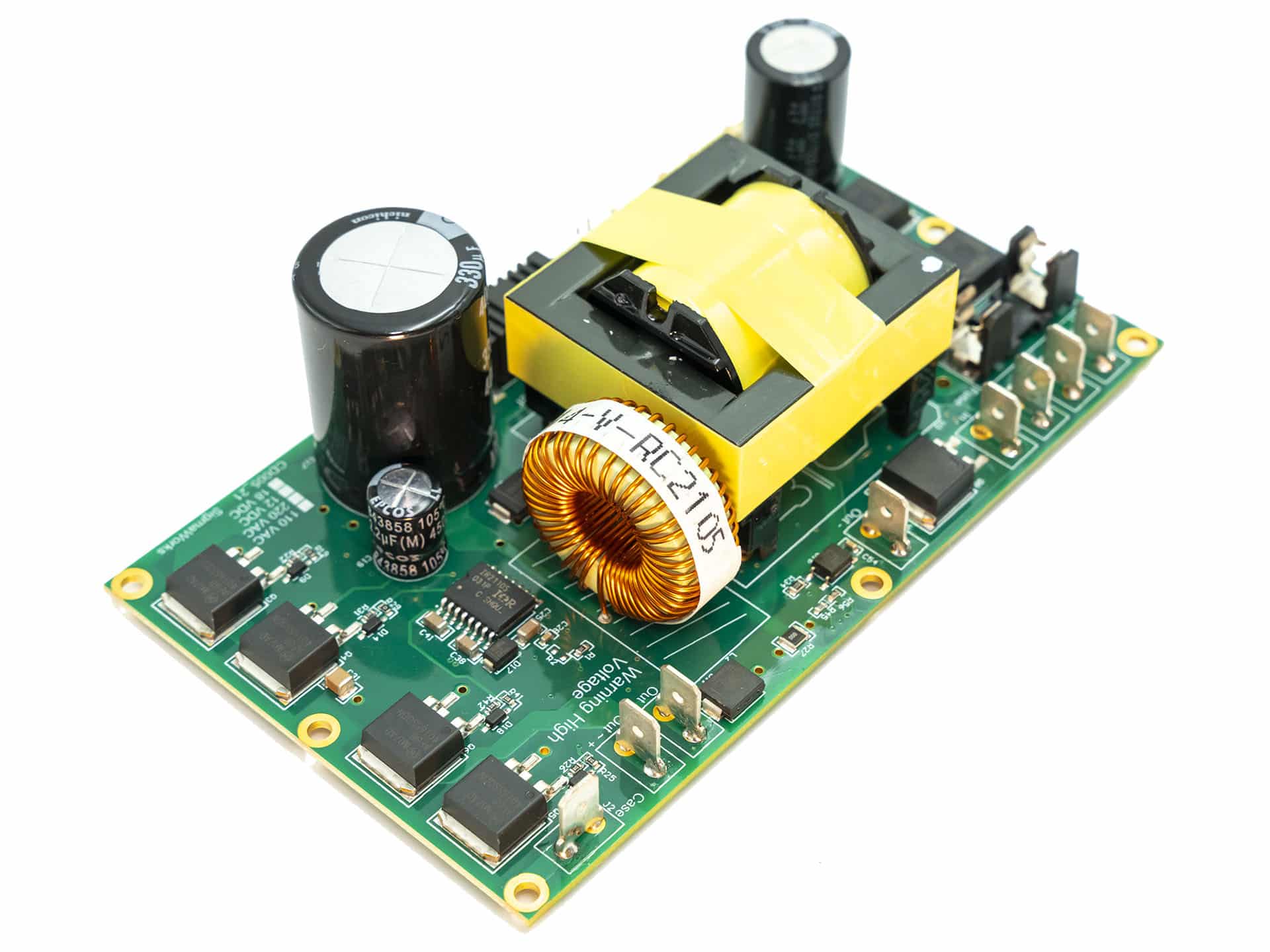

The duty cycle refers to the maximum activation time of your mag yoke before it begins to overheat. This is a crucial concept for preserving the integrity of your electromagnetic yoke. The duty cycle is directly dependent on the sizing of the electromagnet’s air gap and its ability to dissipate heat. To manage this parameter automatically, among others, we have integrated a microcontroller into our “Magnetix” range of battery-powered magnetic particle inspection kits.

Electronic Reliability

Activating mag yoke generates significant reactive power. Without proper management, this reactive current can cause overheating in the inverter’s output stage, potentially causing irreversible damage. The DC/AC transformers commonly available on the mpi inspection market are often just standard electronic components, not specific to the unique needs of powering electromagnets. This oversight leads to many issues of electronic reliability in existing portable magnetic particle inspection test systems. As experts in power electronics, we design our own electronic boards, specially crafted to manage the reactive power generated by the electromagnet. Our boards, driven by a microcontroller, analyze in real-time, several thousand times per second, the constants of the inverter such as voltage, current, and temperature. This ensures an extremely reliable power system for your mag particle yoke.

Connectivity Reliability

The integrity of cables and electrical connections is critical in mpi welding test systems, particularly for portable mpi yokes where the risk of cable laceration or detachment is high in field conditions. We pay special attention to these aspects in our products, especially in our Magnetix range of ac yokes. While we do not claim to offer an indestructible solution, we have adopted the most robust measures possible to address these challenges.

Our cables are made of polyurethane, an extremely abrasion and laceration-resistant thermoplastic, which also provides good resistance to chemicals. At every cable/gland or cable/connector junction, we have incorporated an injected strain relief for protection, thereby strengthening the connection and effectively managing the cable’s bend at rigid points. We also use waterproof electrical connectors with a quick connect and lock system for all connections.

Design and General Features of Our Magnetix , MPI inspection Kits, MGN 2.0

MGN 2.0

Overview

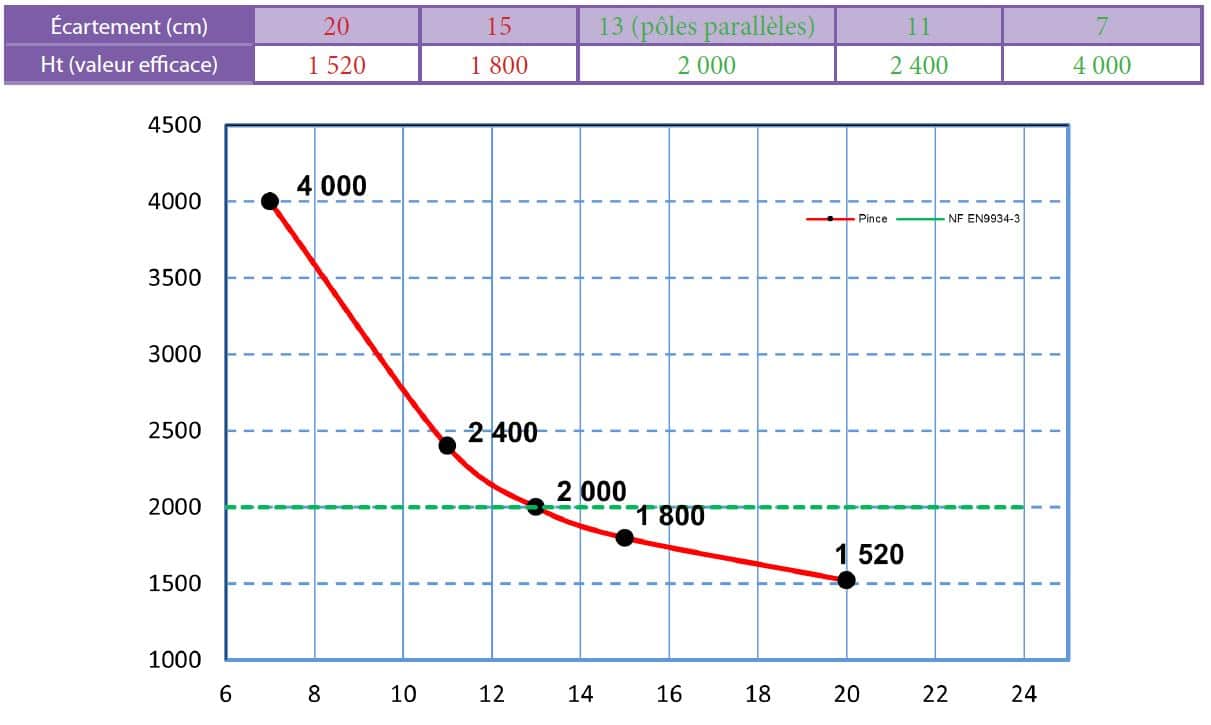

Measurement of Tangential Magnetic Field at Different Pole Distances *

| General Characteristics | Details |

|---|---|

| Working voltage | 220V AC 50HZ |

| Pull Force / Lifting Capacity | > 4.5 Kg |

| Electromagnet Mass | 2.3 Kg |

| Pole section | 20 x 20 mm (4 cm²) |

| Duty Cycle | 25% |

| Protection Rating | IP 54 |

| Battery type | Cordless Li-ion |

| Battery Capacity | 4 Ah |

| Battery Life | Approximately 3 hours at a 25% duty cycle (Space for 4 batteries in the kit, so up to 12 hours) |

| Total Kit Weight (excluding case) | 5.4 Kg |

MGN 2.5

Overview

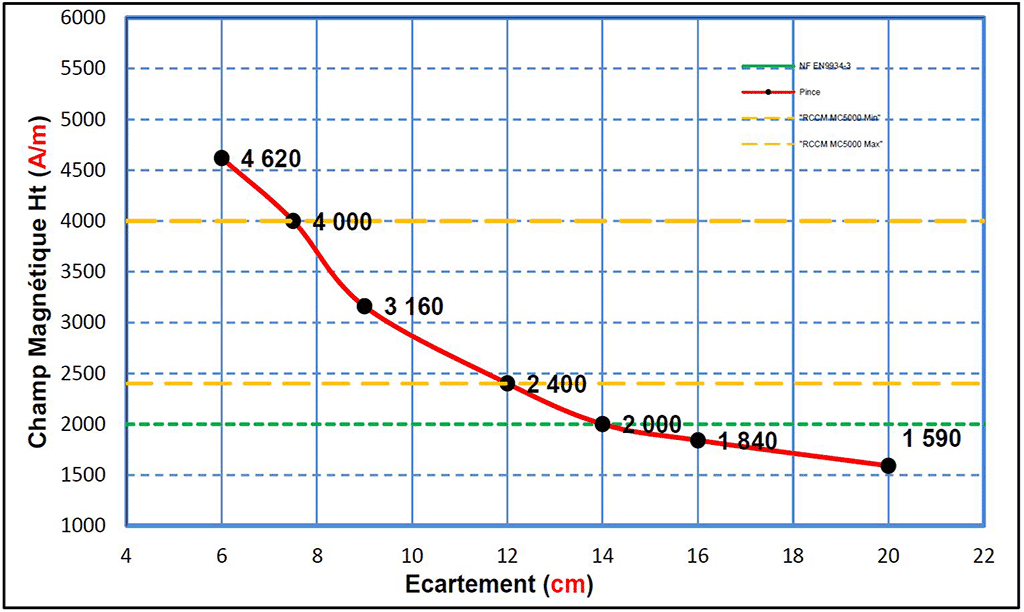

Measurement of Tangential Magnetic Field at Different Pole Distances *

*For reference only, not a specification as it varies with each ac yoke

| General Characteristics | Details |

|---|---|

| Working voltage | 220V AC 50HZ |

| Pull Force / Lifting Capacity | > 4.5 Kg |

| Electromagnet Mass | 2.6 Kg |

| Pole section | 25 x 25 mm (6.25 cm²) |

| Duty Cycle | 50% |

| Protection Rating | IP 54 |

| Battery Type | Cordless Li-ion |

| Battery Capacity | 4 Ah |

| Battery Life | Up to 2 hours at a 50% duty cycle (Space for 4 batteries in the kit, so up to 8 hours) |

| Total Kit Weight (excluding case) | 5.7 Kg |

Usage

Human-Machine Interface (HMI) up to Version 2.5

To monitor the status of your magnetic particle inspection test system, we have developed a Human-Machine Interface (HMI) using the microcontroller on the electronic board. This HMI communicates messages through the modulation or blinking of an LED integrated into the power driver activation button. The messages provide information about the duty cycle, standby states, battery status, temperatures, current control, and more.

Maintenance

Maintaining your battery-operated mpi inspection kit is crucial for ensuring its long-term integrity. Even though everything has been designed and implemented to maximize the lifespan of your kit, regular checks and brief maintenance will help keep it functional over the long term.

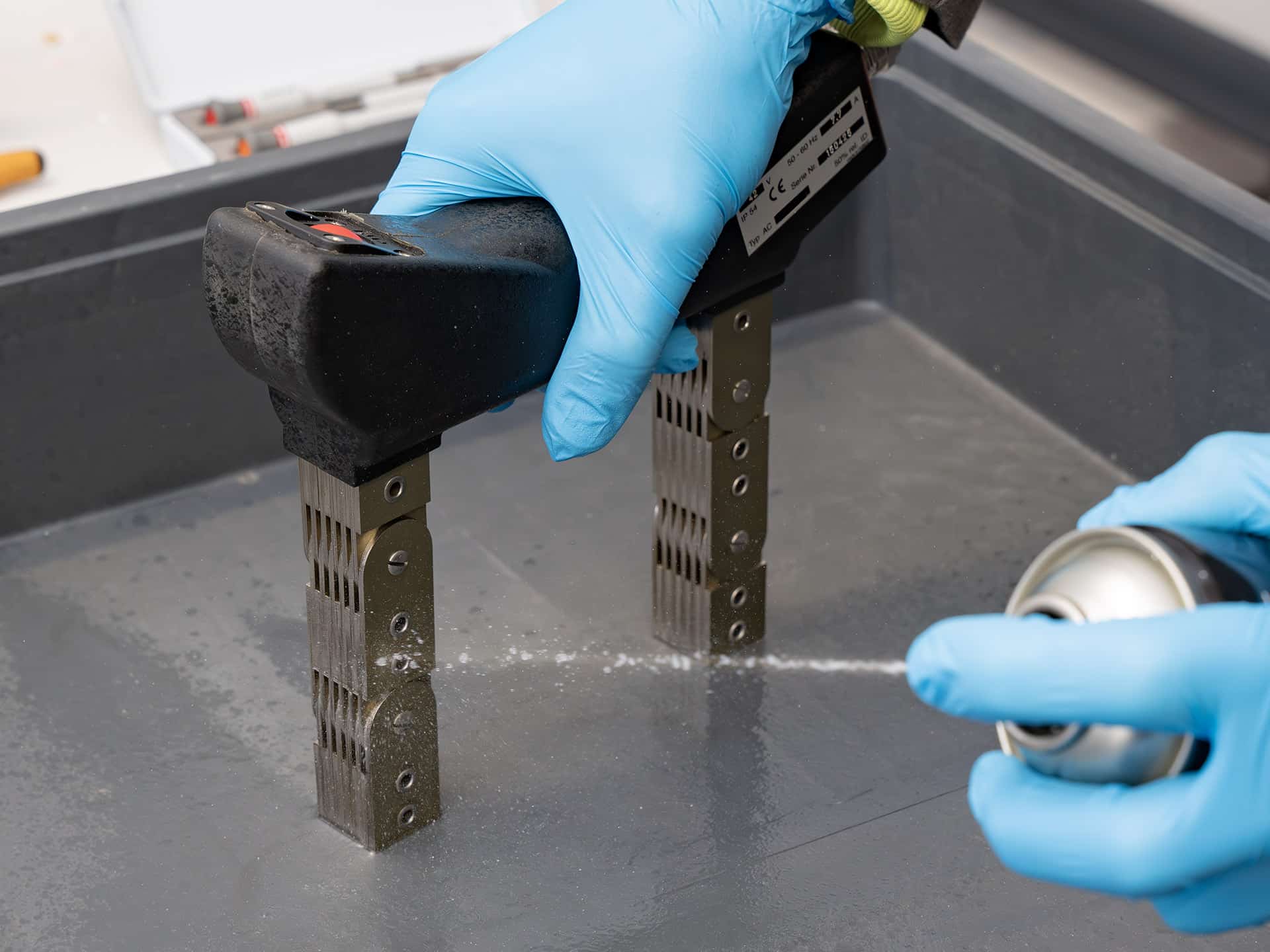

Pole cleaning

It is advisable to regularly clean, lubricate, and check the tightness of the poles of the electromagnet to prevent jamming of the pivots in the air gap of the magnetic particle inspection yoke.

Connectivity Checks

This is the most crucial point to ensure the long-term integrity of your equipment and your safety. Regularly check the tightness of the cable glands both on the yoke side and the power driver side, as well as the general condition of the cables. If any laceration occurs, it is necessary to send your magnetic particle test welding system for maintenance to avoid any risk of short-circuit, electrocution, or detachment.

Control Standards

Magnetic particle testing is regulated by a series of standards that establish precise guidelines on how tests should be performed to ensure their effectiveness.

The current standards for mpi magnetic particle inspection include, among others:

NF EN ISO 9934-1: Non-destructive testing – Magnetic particle testing – Part 1: General principles

NF EN ISO 9934-2: Non-destructive testing – Magnetic particle testing – Part 2: Detection media

NF EN ISO 9934-3: Non-destructive testing – Magnetic particle testing – Part 3: Equipment

ASTM E709: Standard Guide for Magnetic Particle Testing