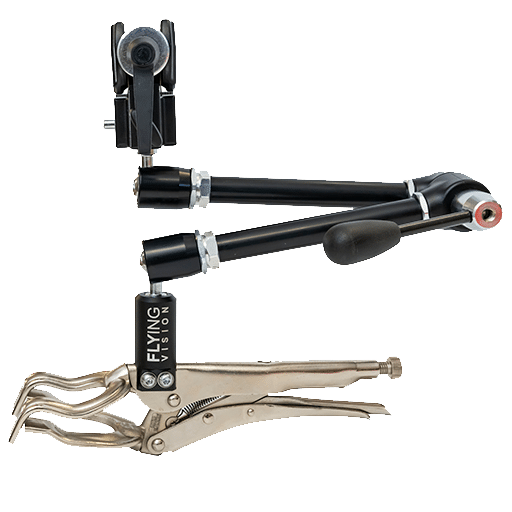

Gamma Positioning Tool (OPG)

Non-contractual photo

Push the limits of precision in industrial radiography!!!

The OPG is an innovative instrument specifically designed to optimize the positioning of the radioactive source or collimator during controls by industrial radiography or industrial gammagraphy in the demanding field of Non-Destructive Testing (RT). This positioning accessory or collimator support ensures the immobility and precise positioning of the source, thus allowing for exact localization and repeatable control results. The operational efficiency provided by the OPG translates into time and money savings for companies, all while maintaining the integrity and accuracy of inspections. Its robust and functional design makes the OPG an essential ally for all NDT professionals, wishing to increase the productivity and reliability of their industrial gammagraphy operations.

Contexte et field of application

In the demanding field of Non-Destructive Testing (NDT RT) by industrial radiography and industrial gammagraphy, the accuracy and stability of the radioactive source positioning are crucial to ensure the quality and reliability of the inspections. Gamma clamps or ellipse clamps, primarily serving as collimator supports, are indispensable tools to guarantee the precision of the controls, the immobility of the source, and accurate localization.

These specialized tools are essential in sectors such as the petrochemical industry, shipbuilding, energy production, and aeronautics, where every detail matters. They afford operators the ability to position the source quickly and accurately, which translates to significant time and money savings for companies. The repeatability of the control, ensured by the use of these accessories for gammagraphy, also contributes to the optimization of the inspection processes, thereby enhancing confidence in the safety and quality of the inspected structures and components.

Complete Guide to Magnetic Particle Inspection for Non-Destructive Testing (NDT MT)

Introduction

Industrial Gammagraphy (Industrial Radiography Testing, RT) is a method of Non-Destructive Testing (NDT) that employs ionizing radiation to examine the integrity and the internal structure of materials. This technique is widely used in sectors such as aerospace, oil, construction, and metal manufacturing to detect defects such as cracks, inclusions, porosities, and other anomalies that cannot be seen on the surface.

Principle and importance of accessories

Using ionizing radiation from sources such as iridium-192 or selenium-75, this method creates radiographic images that reveal the internal structure of materials. Source positioning accessories like gamma clamps or ellipse clamps are crucial for precisely placing the radioactive source and obtaining clear and detailed images.

Process

- Sample preparation :

Cleaning and accessibility of the object are essential. Source positioning accessories are used to prepare the sample.

- Source positioning :

Thanks to ellipse clamps for gammagraphy and accessories for gammagraphy, the source and the detector are optimally positioned on either side of the object.

- Exposure :

The source, well-positioned using clamps for gammagraphy, emits radiations to create an image on a film or a digital detector.

- Interpretation :

The obtained images are then examined by a specialist to identify any anomalies and assess the quality of the components.

Importance

Industrial gammagraphy is vital for ensuring quality and safety in the industry. It allows for the early detection of defects, thus minimizing the risks of failure and extending the lifespan of the components.

Standards

Adherence to AFNOR standards such as NF EN ISO 5579, NF EN 12681, and NF EN ISO 17636 is fundamental to ensure the quality and consistency of results in industrial gammagraphy. These standards guide NDT professionals in the application and interpretation of radiographic methods.

Conclusion

In summary, the use of specific accessories and adherence to current standards are key elements in the success of industrial gammagraphy inspections, thus contributing to safety and quality in the industry.

Nomenclature

- Central locking articulated arm

- Clamp for securing the gamma clamp to any type of support

- Locking system for the Gamma source

ADVANTAGES

Performance

Articulated arm allowing easy adjustment of the collimator in any position, thereby optimizing the precision and repeatability of radiographic inspections.

Quality

Robust and reliable design for intensive use, ensuring a long tool lifespan.

Features

Versatile mounting options on various types of supports

Versatile clamping vise, adaptable to any type of support up to 90 mm in diameter, providing great flexibility during inspection operations.

Quick locking of the shooting position

Articulated arm allowing easy adjustment of the collimator in any position, optimizing the execution of radiographic shots.

Composition of the kit

1 x Articulated gamma clamp including:

- Clamp for securing the clamp on various

- supportsSource locking system

Characteristics

| Technical characteristics | Details |

|---|---|

| Weight | 2300 grams |

| Articulated arm dimensions | 50 cm |

| Clamping capacity of the vice grips | up to 90 mm in diameter |

| Collimator Side Clamping Capacity | from 13 to 55 mm for tube and flat surface |

| Materials | Anodized aluminum, stainless steel |

Downloadable files:

-

Product brochureProduct brochure